Supplier of

uNIQUE PURE LIPOSOMAL VITAMINS AND MINERALS IN POWDER FORM

Available in bulk powder form, encapsulated or private label.

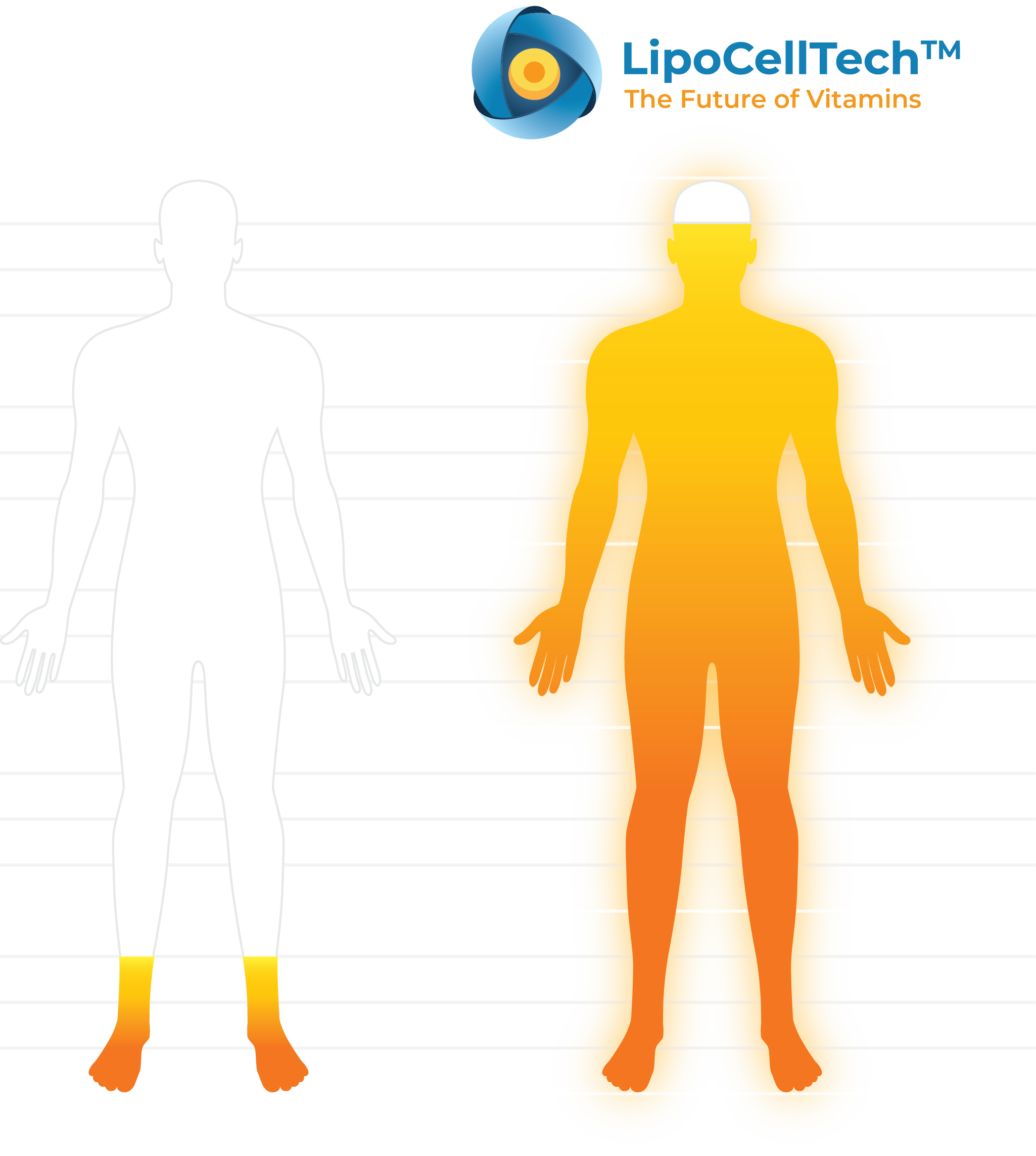

The problem of bad absorption of regular supplements

It is a scientific fact that most non-liposomal supplements have a very poor absorption and bio-availability rate. In addition, excipients, binders, fillers and flow agents can also contribute to poor disintegration rates which means poor absorption at best. The next problem is to ensure that the active ingredients move into the blood stream and reach the cells. This is explained in this video.

The Problem of bad absorption of regular supplements

It is a scientific fact that most non-liposomal supplements have a very poor absorption and bio-availability rate. In addition, excipients, binders, fillers and flow agents can also contribute to poor disintegration rates which means poor absorption at best. The next problem is to ensure that the active ingredients move into the blood stream and reach the cells. This is explained in this video.

The Solution

It is a scientifically proven fact that liposomal supplements have a high absorption and bioavailability rate. Our dry-liposomal manufacturing process is unique on the market, because it uses no heat, no high pressure, no chemicals and no spray or freeze-drying.

Our liposomal supplements contain only active ingredients and phospholipids, no flavours, perservitaives or other additives, this way our powders are a 100% pure.

The Solution

It is a scientifically proven fact that liposomal supplements have a high absorption and bioavailability rate. Our dry-liposomal manufacturing process is unique on the market, because it uses no heat, no high pressure, no chemicals and no spray or freeze-drying.

Our liposomal supplements contain only active ingredients and phospholipids, no flavours, perservitaives or other additives, this way our powders are a 100% pure.

Unprecedented

high bioavailability

The liposomal production of medicine, vitamins, and minerals has been successfully used for many years to improve the absorption of these substances by the body. Depending on the ingredient, absorption may increase by a factor of up to 20. Many scientific studies around the world support this.

Liposomals for vitamins have been on the market since 2004. There are liquid liposomal products as well as powdered forms which are generally encapsulated.

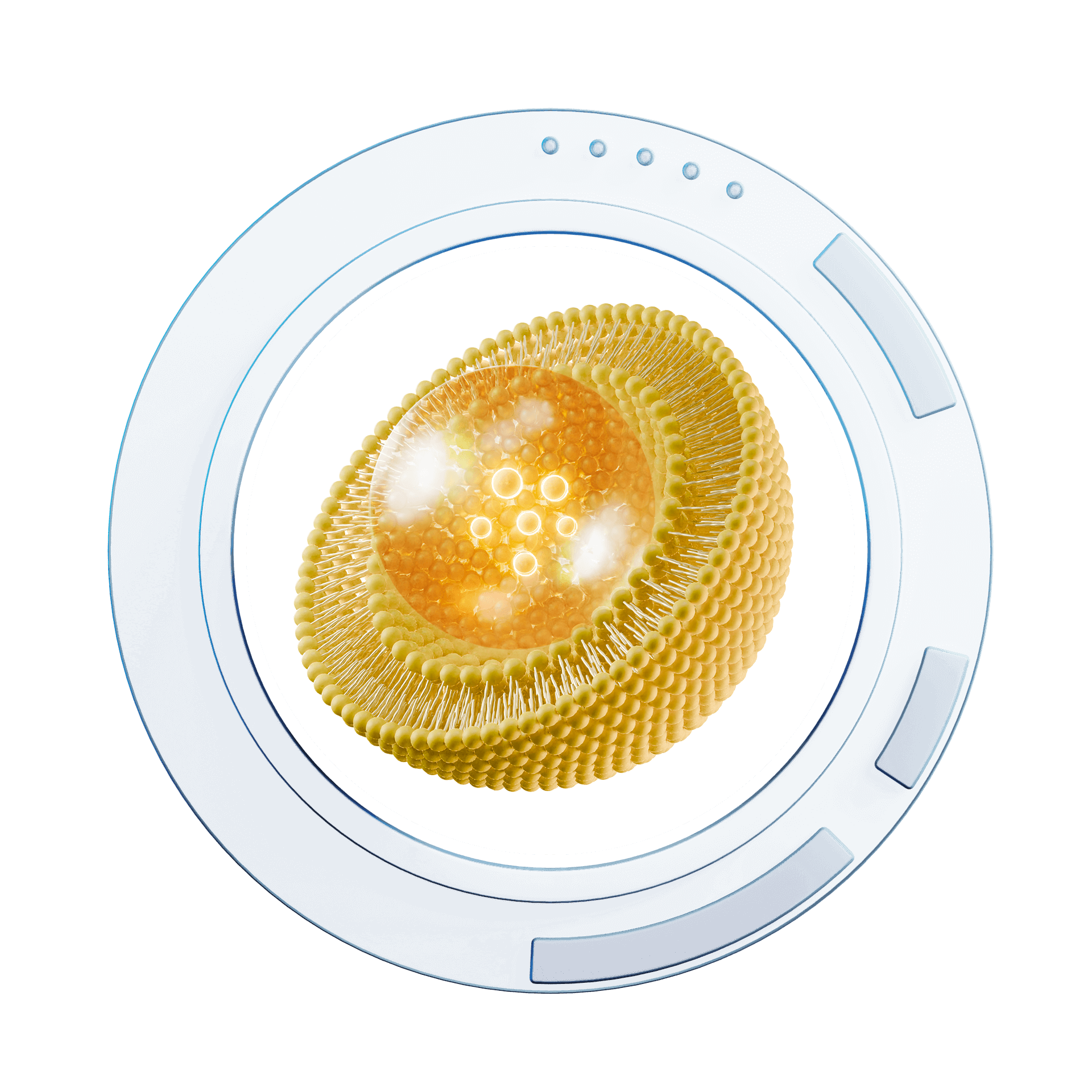

Over the years various production methods have been evolved. LipocellTech™ makes use of the most advanced production method of liposomal products in powder form. This production method has its origin in nature.

Unlike other production processes, where it can be quite common, LipocellTech does not use heat, high pressure or chemicals. As a result, our liposomal products are 100% natural and are virtually completely absorbed into the body.

Unprecedented high bioavailability

The liposomal production of medicine, vitamins, and minerals has been successfully used for many years to improve the absorption of these substances by the body. Depending on the ingredient, absorption may increase by a factor of up to 20. Many scientific studies around the world support this.

Liposomals for vitamins have been on the market since 2004. There are liquid liposomal products as well as powdered forms which are generally encapsulated.

Over the years various production methods have been evolved. LipocellTech™ makes use of the most advanced production method of liposomal products in powder form. This production method has its origin in nature.

Unlike other production processes, where it can be quite common, LipocellTech does not use heat, high pressure or chemicals. As a result, our liposomal products are 100% natural and are virtually completely absorbed into the body.

The advantages of LipoCelltech™ liposomes over other versions

More Than 90% Encapsulation rate; the highest on the market

The percentage of active ingredients that is actually encapsulated by a double layer of phospholipids in liposomal liquid and powder forms on the market can vary significantly. It is not unusual that the percentages are as low as 10 to 20 %.

In our liposomals powder more than 90 % of the supplement in the product is encapsulated by a double layer of phospholipids, the highest percentage on the market.

Our newly developed production process makes this possible. This is confirmed by an encapsulation efficiency test. The standard test for measuring the percentage of liposomes in a product.

Purity

In other liposomal products on the market, there are additives such as flavors, preservatives and other chemicals. Unfortunately, there is a risk of these additives entering a liposome and being transported into the body’s cells where they don’t belong.

Our liposomal products only contains phospholipids and the active ingredients which makes it a safe and pure product.

Shelflife

Liquid forms have a short shelf life and problems with stability. Consequently, the liposomes will fall apart. Our finished products have a shelf life of 3 years confirmed by stability testing.

Production Process

Most liposomal production methods use freeze drying, spray drying, heat, pressure, or chemicals—breaking down liposomes and damaging active ingredients. Our production process uses none of these methods. After years of development, we have found a way to avoid all these factors, copying the way nature makes liposomes.

The advantages of LipoCelltech™ Liposomes over other versions

More Than 90% Encapsulation rate; the highest on the market

The percentage of active ingredients that is actually encapsulated by a double layer of phospholipids in liposomal liquid and powder forms on the market can vary significantly. It is not unusual that the percentages are as low as 10 to 20 %.

In our liposomals powder more than 90 % of the supplement in the product is encapsulated by a double layer of phospholipids, the highest percentage on the market.

Our newly developed production process makes this possible.

Our percentage is confirmed by an encapsulation efficiency test, the standard test for measuring the percentage of liposomes in a product.

Purity

In other liposomal products on the market, there are additives such as flavors, preservatives and other chemicals. Unfortunately, there is a risk of these additives entering a liposome and being transported into the body’s cells where they don’t belong.

Our liposomal products only contains phospholipids and the active ingredients which makes it a safe and pure product.

Shelf life

Liquid forms have a short shelf life and problems with stability. Consequently, the liposomes will fall apart. Our finished products have a shelf life of 3 years confirmed by stability testing.

Production Process

When production flow charts of other liposomal products are examined, you will see that freeze drying and spray drying is used. This breaks down the liposomal structure. In addition, the use of heat and pressure to produce a liposome will damage the active ingredients. Additionally, even chemicals can be used in these production processes.

Our production process uses none of these methods. After years of development, we have found a way to avoid all these factors, copying the way nature makes liposomes.

Science

The quality of our liposomal products is backed by science. The general use of liposomes has been backed by many pharmaceutical studies and need no further introduction. In addition, LipoCellTech™ conducts its own studies, which can be found on the website.

Science

The quality of our liposomal products is backed by science. The general use of liposomes has been backed by many pharmaceutical studies and need no further introduction. In addition, LipoCellTech™ conducts its own studies, which can be found on the website.

The Highest Standard

LipoCellTech™ guarantees quality. The production facility is GMP-certified, and we adhere to strict quality procedures. That’s why each step of the manufacturing process is carefully documented and tested. From start to finish of the production, storage and shipping process we adhere to HACCP standards and hold a HACCP certificate.

GMP (Good Manufacturing Practice) is a system for ensuring that products are consistently produced and controlled according to quality standards.

HACCP (Hazard Analysis Critical Control Point) is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Safety, efficacy, and quality are three important pillars within our company. We work according to the strictest ethical standards, and highly value long-term relationships with our clients. According to our vision, this can only be done by delivering constant quality and continuous improvement.

100% Pure Fill

Experience transparency and purity, our products contain no fillers or additives, delivering only the highest quality ingredients.

GMP Certified

Our products meet rigorous quality standards with GMP certification, ensuring consistency and safety in every batch.

HACCP Certified

We prioritize food safety with HACCP certification, guaranteeing meticulous monitoring and control throughout production.

The Highest Standard

LipoCellTech™ guarantees quality. The production facility is GMP-certified, and we adhere to strict quality procedures. That’s why each step of the manufacturing process is carefully documented and tested. From start to finish of the production, storage and shipping process we adhere to HACCP standards and hold a HACCP certificate.

GMP (Good Manufacturing Practice) is a system for ensuring that products are consistently produced and controlled according to quality standards.

HACCP (Hazard Analysis Critical Control Point) is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Safety, efficacy, and quality are three important pillars within our company. We work according to the strictest ethical standards, and highly value long-term relationships with our clients. According to our vision, this can only be done by delivering constant quality and continuous improvement.

100% Pure Fill

Experience transparency and purity, our products contain no fillers or additives, delivering only the highest quality ingredients.

GMP Certified

Our products meet rigorous quality standards with GMP certification, ensuring consistency and safety in every batch.

HACCP Certified

We prioritize food safety with HACCP certification, guaranteeing meticulous monitoring and control throughout production.

Get in touch

with us today

Seeking premium liposomal supplements for your business? We're ready to discuss wholesale terms, product specifics, and collaboration opportunities. Let's grow together!

LipoCellTech™ Head office

Kerkplein 9-G • 3764 AW Soest • The Netherlands

LipoCellTech™ Head office

Kerkplein 9-G • 3764 AW Soest • The Netherlands

LipoCellTech™ UK

Down Park Coach House • Turners Hill Road Crawley Down West Sussex • RH10 4HQ • United Kingdom

LipoCellTech™ USA

535 Rogers Street • Clearwater, FL 33756 • United States

Give us a call

+31 (0)35 3039 150

"*" indicates required fields